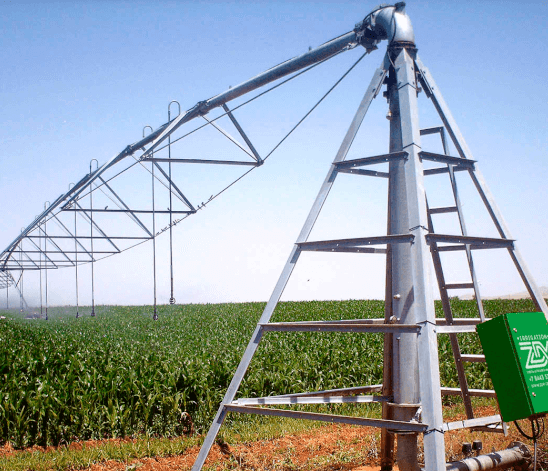

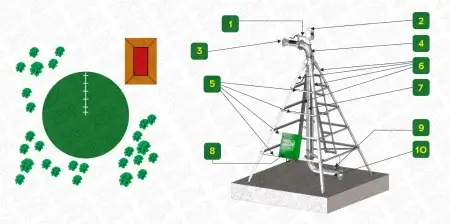

Center Pivot Irrigation Machine (Stationary)

ZDM center pivot irrigation machine installation

Installation is carried out by certified specialists of the ZDM-Irrigation Plant service department or an official ZDM dealer.

✅ The process is standardized — only basic equipment and special machinery are required.

-

In stock

-

Limited offer quantity

Share: